The simple answer is that it took a journey along the fashion supply chain. But what is a supply chain?

“A supply chain consists of all stages involved, directly or indirectly, in fulfilling a customer request. The supply chain not only includes the manufacturer and suppliers, but also transporters, warehouses, retailers and customers themselves.” (Chopra, Sunil, and Peter Meindl, 2003, Supply Chain, Second Edition, Upper Saddle River, NJ: Prentice-Hall, Inc., Chapter 1).

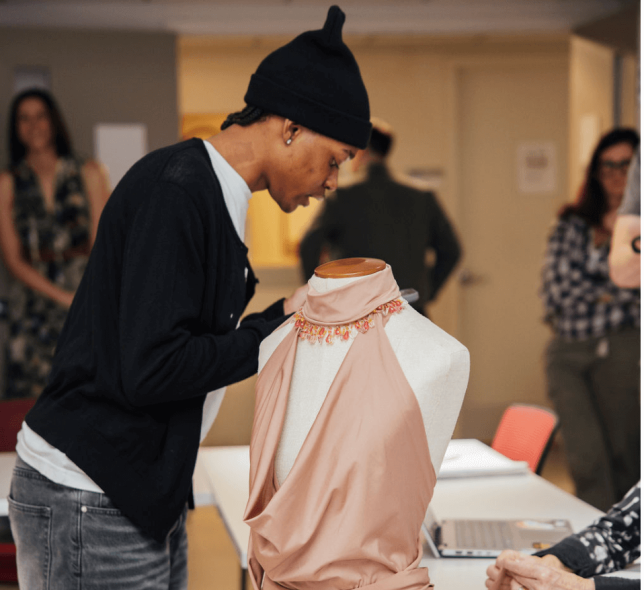

Design and Development

To break this definition down a bit further you need to take into account the design and development of the shirt.

Did it start as a hand sketch, or was it created through the use of technology, such as a computer-aided design program? Did the designer then determine what raw materials (in this case the fabric and trims) would be best suited for their target market? Does your company have the finances in place to produce the shirt? https://www.oracle.com/retail/fashion/fashion-supply-chain

Once these decisions have been made, it transitions to a technical designer (or product development specialists, sometimes called merchandisers) to create a "technical package" that is sent to the factory to create a sample. Once the sample is approved and all the raw materials have been gathered, the shirt moves into the production phase.

Production

Decisions are made along the way as to where the best place to produce the shirt would be. Which country can provide the best price at the right quality level and with the best lead time needed to produce the shirt? These decisions will likely be made ahead of time based on existing relationships with factories around the globe.

Once the production has been completed, it is time to inspect the shirts to make sure that the factory has adhered to the quality control standards you established.

If the shirts pass inspection, the company that produced it would "draw down the letter of credit" This means they get paid for their work. Transportation of the shirts is then arranged, and if they are coming from a factory in another part of the world and a large quantity of them has been produced, it will most likely mean the shorts get loaded into a container and placed on a ship.

Logistics and Transportation

With transportation time factored in and customs clearance established, duties (aka tariffs) are paid to the U.S. government. Then the shirts are delivered to a warehouse in the U.S. where they are processed and shipped to your favorite store.

It may sound simple, but the reality is that getting a shirt on to a rack in your favorite store is a very complex process. It involves many people and takes a lot of time. Producing a large number of shirts in a country halfway around the world can take up to six months from start to finish.